Cov pwm feem ntau tsuas muaj cov kab noj hniav thiab tsis muaj punch.Cov pwm saum npoo feem ntau tsis tas yuav tsum tau hardened.Lub tshuab siab los ntawm kab noj hniav yog me dua li ntawm kev txhaj tshuaj molding, feem ntau 0.2 ~ 1.0MPG, thiab tus nqi qis.

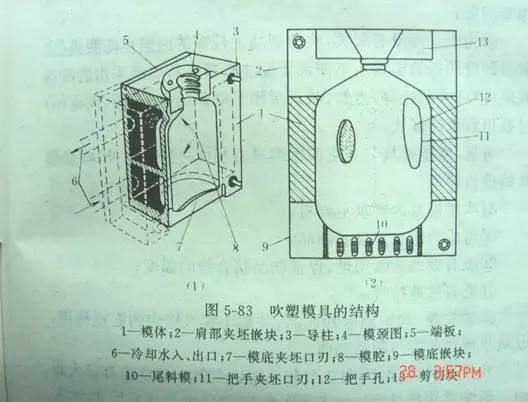

Tshuab mould qauv daim duab

Cov khoom siv pwm

Feem ntau, aluminium alloy yog siv rau kev tsim, thiab beryllium tooj liab lossis tooj liab hauv paus alloy tseem siv rau cov khoom siv roj hmab xws li PVC thiab POM.Rau cov pwm uas muaj kev pabcuam siab dua, xws li tshuab moulding engineering yas ABS, PC, POM, PS, PMMA, thiab lwm yam., stainless hlau yuav tsum tau siv los ua pwm.

pwm

Cov ntsiab lus tseem ceeb ntawm kev tsim pwm

Parting nto

Feem ntau, nws yuav tsum tau muab tso rau ntawm lub dav hlau symmetry kom txo tau lub tshuab nthuav dav.Piv txwv li, rau cov khoom lag luam elliptical, qhov chaw seem yog nyob rau ntawm qhov ntev axis, thiab rau cov khoom loj, nws dhau los ntawm txoj kab nruab nrab.

Kab noj hniav

PE cov khoom yuav tsum yog me ntsis ntxhib, thiab cov xuab zeb zoo yog qhov tsim nyog rau kev tso pa tawm;Rau tshuab moulding ntawm lwm yam yas (xws li ABS, PS, POM, PMMA, NYLON, thiab lwm yam), lub pwm kab noj hniav feem ntau tsis tuaj yeem sandblasted, thiab qhov tso pa tawm tuaj yeem ua rau ntawm qhov chaw ntawm cov pwm kab noj hniav, lossis cov pa tawm. Lub qhov tuaj yeem ua rau ntawm pwm kab noj hniav, thiab txoj kab uas hla ntawm lub qhov tso tawm ntawm cov pwm kab noj hniav φ 0.1 ~ φ 0.3, ntev 0.5 ~ 1.5mm.

Kab noj hniav loj

Lub shrinkage tus nqi ntawm cov yas yuav tsum tau txiav txim siab nyob rau hauv tus tsim ntawm kab noj hniav loj.Yog xav paub meej, thov xa mus rau cov nqi ntawm cov yas shrinkage.

Txiav ntug thiab tailing groove

Feem ntau, rau tshuab moulding engineering plastics thiab cov yas tawv tawv, kev txiav ntug yuav tsum tau ua los ntawm cov ntaub ntawv uas muaj kev hnav zoo, xws li beryllium tooj liab, stainless hlau, thiab lwm yam. Rau LDPE, EVA thiab lwm yam khoom siv yas mos, aluminium alloy yuav siv tau. .

Cov ntug txiav yuav tsum tau xaiv nrog qhov tsim nyog loj.Yog tias nws me dhau lawm, nws yuav txo tau lub zog ntawm kev sib koom tes.Yog tias nws loj dhau lawm, nws tsis tuaj yeem txiav thiab lub clamping ntug ntawm qhov sib cais yog loj.Txawm li cas los xij, lub tailing zawj yog qhib hauv qab ntawm qhov txiav, thiab lub tailing groove yog tsim los ua lub kaum sab xis.Thaum txiav, me me ntawm cov yaj tuaj yeem nyem rau hauv qhov sib koom ua ke, yog li txhim kho lub zog ntawm kev sib koom tes.

Txhaj tshuab mould

Tus tsim yog txawv los ntawm extrusion tshuab molding.Qhov sib txawv tseem ceeb yog qhov txhaj tshuaj pwm tsis tas yuav txiav cov ntug thiab tailing groove.Cov qauv dawb ntawm kev txhaj tshuaj tshuab yog qhov tseem ceeb heev, uas cuam tshuam ncaj qha rau qhov zoo ntawm cov khoom tiav.

Txhaj pwm - parison tsim qauv

1. Ntev, txoj kab uas hla thiab qhov ntev ≤ 10/1

2. Tshuab nthuav dav piv 3/1 ~ 4/1 (qhov piv ntawm cov khoom loj rau parison loj)

3. Phab ntsa thickness 2 ~ 5.0mm

4. Raws li cov duab ntawm cov khoom, cov phab ntsa thickness yog thicker qhov twg lub tshuab piv yog loj, thiab thinner qhov twg lub tshuab piv yog me me.

5. Rau cov thawv ntim elliptical uas muaj qhov sib npaug ntawm cov ellipse ntau dua 2/1, cov tub ntxhais qws yuav tsum tau tsim los ua ib qho ellipse.Rau cov khoom lag luam elliptical nrog qhov sib piv ellipse tsawg dua 2/1, cov tub ntxhais puag ncig tuaj yeem tsim lub thawv ellipse.

Tshuab raj tsim

Cov qauv ntawm lub tshuab cua tshuab yog txiav txim siab raws li cov qauv pwm thiab cov khoom yuav tsum tau ua.Feem ntau, kev xaiv ntau yam ntawm lub qhov taub ntawm cov pa nqus pa pas nrig yog:

L<1: aperture φ one point five

4> L> 1: aperture φ rau taw tes tsib

200>L> 4: aperture φ 12.5 (L: ntim, unit: litre)

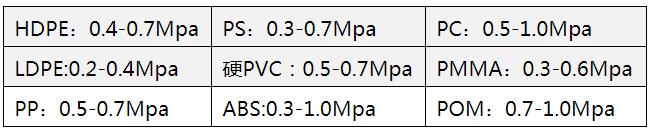

Cua siab ntawm hom yas tshuab molding

Post lub sij hawm: Mar-22-2023