Tshuab moulding feem ntau suav nrog extrusion tshuab moulding (EBM), txhaj tshuaj stretch tshuab moulding (ISBM) thiab txhaj tshuaj molding (IBM).Nws yog txheej txheem molding tshwj xeeb uas siv rau kev tsim khoom loj ntawm cov thawv yas hollow.Qhov teeb meem no qhia peb hom tshuab molding txheej txheem: extrusion tshuab moulding (EBM).

Tus nqi txheej txheem: tus nqi ua haujlwm (nruab nrab), ib qho nqi (qis);

Cov khoom lag luam: ntim ntim rau cov khoom siv tshuaj, ntim ntim rau cov khoom siv, thiab ntim ntim rau cov tshuaj;

Tsim nyog cov zis: tsuas yog haum rau loj ntau lawm;

Zoo: zoo zoo, zoo tib yam phab ntsa thickness, kho nto haum rau du, frosted thiab textured;

Ceev: ceev, 1-2 feeb ib ncig ntawm qhov nruab nrab.

Tshuab molding muab faib ua peb pawg

1. Extrusion tshuab moulding (EBM): Tus nqi qis tshaj piv nrog rau ob hom, thiab nws tsim nyog rau kev tsim cov yas (PP, PE, PVC, PET) hollow ntim nrog ntim ntawm 3 milliliters rau 220 litres. .

2. Txhaj tshuab moulding (IBM): yuav tsum tau txuas ntxiv.

3. Stretch tshuab molding (ISBM): yuav tsum tau txuas ntxiv.

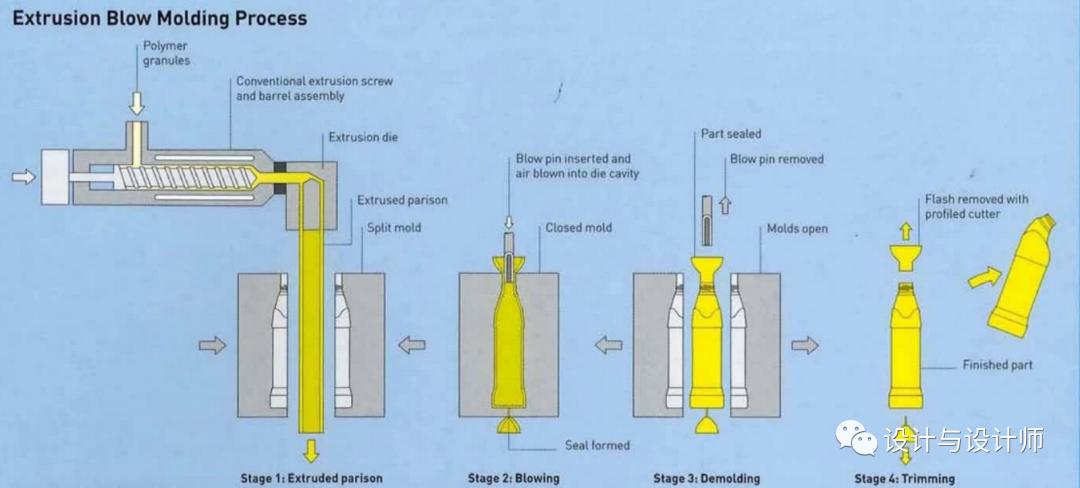

1. Extrusion tshuab moulding (EBM) cov kauj ruam:

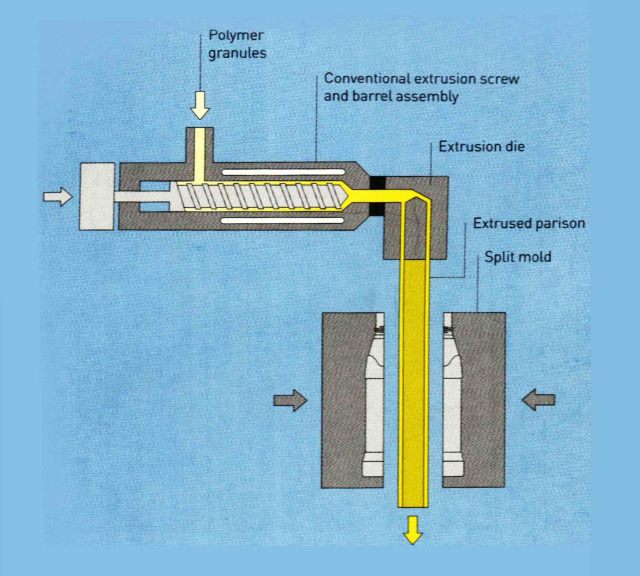

Kauj Ruam 1: Ncuav cov khoom polymer rau hauv cov pwm tawv, thiab tsim ib qho colloidal hollow kem-zoo li tus qauv los ntawm cov cua sov thiab nruam extrusion ntawm mandrel.

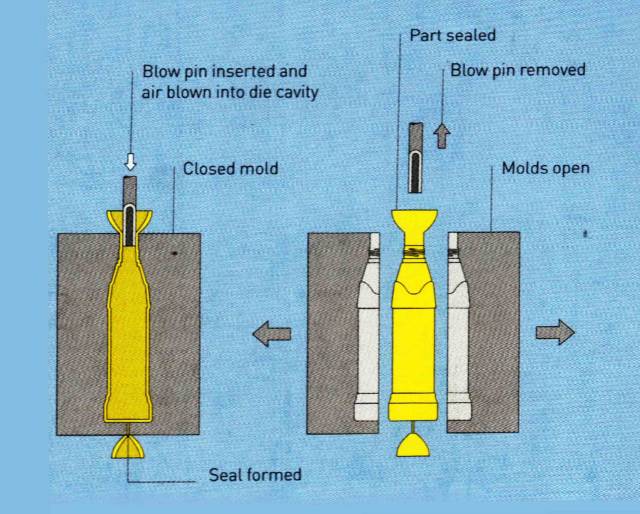

Kauj Ruam 2: Thaum lub hollow cylindrical qauv yog extruded mus rau ib qho ntev, cov pwm ntawm sab laug thiab sab xis pib kaw, sab saum toj ntawm tus qauv yuav raug txiav los ntawm cov hniav mus rau qhov ntev ntawm ib daim, thiab cov huab cua. yuav raug txhaj rau hauv tus qauv los ntawm tus pas nrig inflatable kom tus qauv nyob ze rau sab hauv phab ntsa ntawm cov pwm kom txias thiab khov kho kom ua tau raws li qhov xav tau.

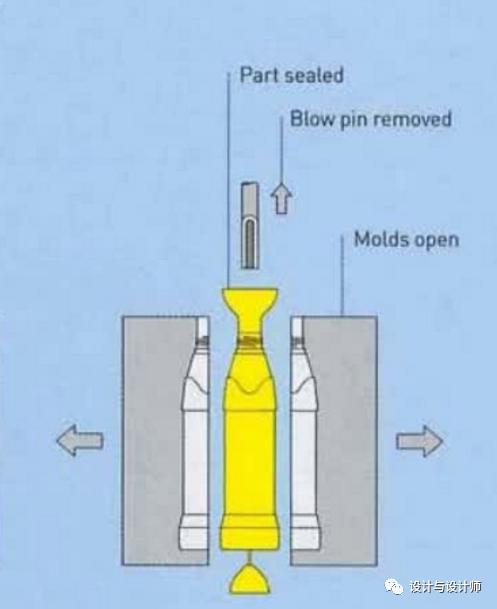

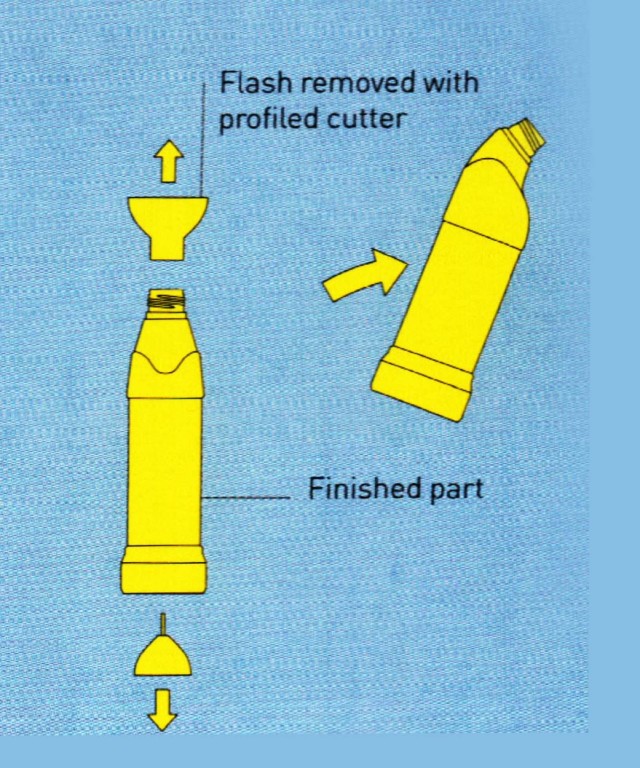

Kauj Ruam 3: Tom qab qhov txias dhau lawm, cov pwm ntawm sab laug thiab sab xis qhib thiab cov khoom raug demoulded.

Kauj ruam 4: Siv cov cuab yeej kho kom luas ib feem.

Post lub sij hawm: Mar-21-2023